Home » Production of Kratom

Production of Kratom

- Anthony Dent, Founding Member

- One Comment

-Kratom Production: How the process can impact the final product.

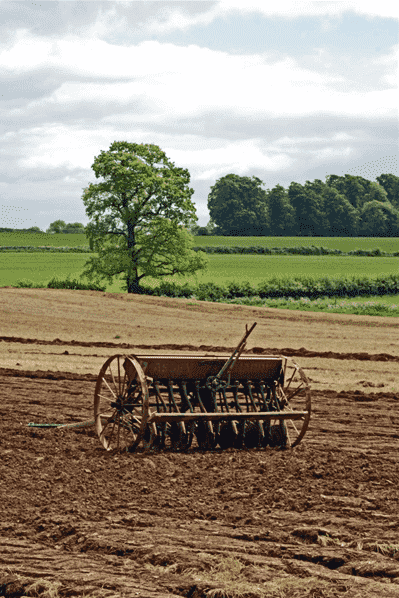

It is posited that a modern society is actually contrary to the innate dispositions of man. So much of our history – the majority, in fact – was spent as hunter-gatherers, living in ragged bands of some 50 guideless berry pickers and game trappers. It is from these roots (PUN ALERT) that our ideal dietary guidelines emerge, our dental health is best maintained, and our ideal social functions are fulfilled. And yet…

How awful does that sound? Scrabbling from scruffly bush to another, one bad season or storm away from having a food crisis, with any constraints in mobility or strength creating a scenario where the mangy tribe may starve? Despite being at odds with much of our physiological and cognitive functions, we settled.

And we did not just settle around the basis of long term farms. We did much more than simply grow crops. We stored them. We improved them. We processed them in a way that was superior to our simplistic skill of gathering which enabled us to maximize their utility.

(So when does he get to the whole part about kratom?)

Fret not, my dear plague stricken peoples. For you see, we have done the same with kratom. As our ancestors simply plucked the kratom leaves from its branch, they missed out on the potential of the plant. And so, in line with our much-needed evolution to a pastoral, settled society, the way we process kratom has made for a better experience.

Powdered Kratom

Kratom, in its natural form, is but a leaf. In fact, it is quite unremarkable; even a kratom connoisseur could walk through the jungles of SouthEast Asia, passing by kratom trees without knowing. Much of our historical records of kratom, in which these Pacific cultures used kratom as a medicine for countless ages of yore, show that kratom was simply chewed in this raw leaf form.

But almost all kratom now is powdered. This has occurred for a number of reasons. First is the increased efficiency of production and market. Leaves are more difficult to store, ship, and move. They can become brittle when dry, and thus may end up in many small pieces, making them difficult to work with. Indeed, these dried kratom leaves would be likely to end up as powder anyways as they are handled and brought to market. With the demand of kratom worldwide skyrocketing, it would not be practical to attempt to handle so many leaves.

Second is the increased potential of the powder. Kratom tea, one of its most popular forms of ingestion, is easier to make with a powder; this is much the same to regular tea, in which small, almost powdered pieces of herbs and such are steeped. It allows better coverage area and a more complete utilization of the product within. Powdered kratom is also easier to consume in more controllable doses. It can be weighed and put into capsules, offering more precise amounts then leaves with a stem. And oh yes, that ol’ stem; the stem and its many veins do not make for ideal consumption. By powdering kratom, the stems can be sifted and grated out, making for much better consumption.

Drying and Curing

Many natural products, ranging from strawberries, bananas, and other fruits, to consumable herbs, all the way to cannabis, are dried and cured before consumption. In fact, many of the plants and herbs that we consume have been processed in a way that maximizes their potential. Think of store bought fruits; oftentimes fruits are picked at one time, and left to ripen, to improve their qualities, like juiciness, texture, and flavor.

Much the same occurs with kratom. When a kratom leaf is picked, it is moist, having been connected to a tree with, from the roots, keeps it circulating with water/moisture.This moisture can present long term problems for its storage, as molds and such can form. For this reason, kratom leaves are left out to dry.

Once dry, kratom is cured. Curation is an interesting process for natural plant based products. The best way to understand ‘curing’ a plant would be to think back to fruit, and the process of ripening; it is done to improve the tangible aspects of consumption. Just think: ripening = curing.

The conditions of the environment have a significant impact on the curing process. Light, airflow, temperature, and humidity are some of the factors involved. Even the effects of gravity, like whether or not the plant product is hanging upside down or right side up, impacts the process. When a kratom leaf is curing, chemical processes occur which alter some of the compounds therein. Though unconfirmed, many kratom producers note that the famous strain Maeng Da derives many of its best qualities from the unique curing conditions and additional time. Based on the length of time (longer cure times are often better) and environmental conditions (high humidities that allow the plant to ‘marinate’ and do not shock dry it are better for some plants), the curation process can actually significantly impact the final product.

The process of curing can even be apparent in the marketing of kratom. The color of the kratom leaf can often be altered by its drying and curing process; from this, some vendors take one strain – such as a White Indo – and dry it and cure it for longer than the rest of the batch. This can make the kratom appear lighter in color, perhaps a yellow shade. And thus, the farmer has created “gold kratom”, which is of course not a genetic delineation, but nonetheless may have some merit, as the additional processes can impact the final product to an extent.

—

It’s fascinating, really; that even after harvesting a plant, we can significantly alter its function. A variety of kratom strains are entirely predicated on the post harvest processing techniques, and may have an appreciable difference from its intended product, even if its genetics are identical.

I for one am glad we evolved. We would have no internet, and no ice cream were we still gathering and hunting.

But most of all?

I’m glad the kratom is better.

—

Featured Products

-

From $24.00Select options This product has multiple variants. The options may be chosen on the product page

From $24.00Select options This product has multiple variants. The options may be chosen on the product page -

From $24.00Select options This product has multiple variants. The options may be chosen on the product page

From $24.00Select options This product has multiple variants. The options may be chosen on the product page -

From $24.00Select options This product has multiple variants. The options may be chosen on the product page

From $24.00Select options This product has multiple variants. The options may be chosen on the product page

Explore More Posts

Product Search

Featured Products

-

Pure Kratom Liquid Extract

Rated 4.72 out of 5From $20.00

Pure Kratom Liquid Extract

Rated 4.72 out of 5From $20.00 -

Red Vein Bali Kratom Capsules

Rated 4.70 out of 5From $24.00

Red Vein Bali Kratom Capsules

Rated 4.70 out of 5From $24.00 -

White Horn Kratom Capsules

Rated 4.88 out of 5From $24.00

White Horn Kratom Capsules

Rated 4.88 out of 5From $24.00

Recent Blogs

Follow Us

Strains

Blogs

NEWSLETTER

Sign up for our newsletter!

These statements and products presented on this website have not been evaluated by the Food and Drug Administration FDA. The products mentioned on this website are not intended to diagnose, prevent, treat or cure any diseases or health conditions. Therefore any information on this website is presented solely as the opinions of their respective authors who do not claim in any way shape or form to be medical professionals providing medical advice. The KRTM Company and its owners or employees cannot be held responsible for, and will not be liable for the inaccuracy or application of any information whatsoever herein provided. By purchasing our products you agree that you are aware and in compliance with your local county, state, or federal regulations. Must be 21 years or older to purchase Kratom. The US FDA has not approved kratom as a dietary supplement. We do not ship to the following states, cities and counties in the US where Kratom is banned: Alabama, Arkansas, Indiana, Rhode Island, Vermont, Wisconsin, Sarasota County, FL, Union County, MS, Denver, CO, San Diego, CA, and Jerseyville, IL.

This Post Has One Comment

People that still think kratom is a drug READ HERE!!